Understanding Diecasting: The Course of and Its Functions

Understanding Diecasting: The Course of and Its Functions

Blog Article

Diecasting is one of the most important processes for modern manufacturing. It plays an integral role in creating complicated metal parts that are produced with precision and efficiency. The process involves pushing melting metal at high pressure into mold cavities, which results in components that have exceptional dimensional accuracy and high finish on the surface. As industries evolve and the demand for premium components grows, diecasting is continuing to be a valuable tool, particularly in sectors requiring the mass production of complicated parts. This article will explore the process of diecasting and its benefits, as well as the material choices, and its extensive applications across various industries.

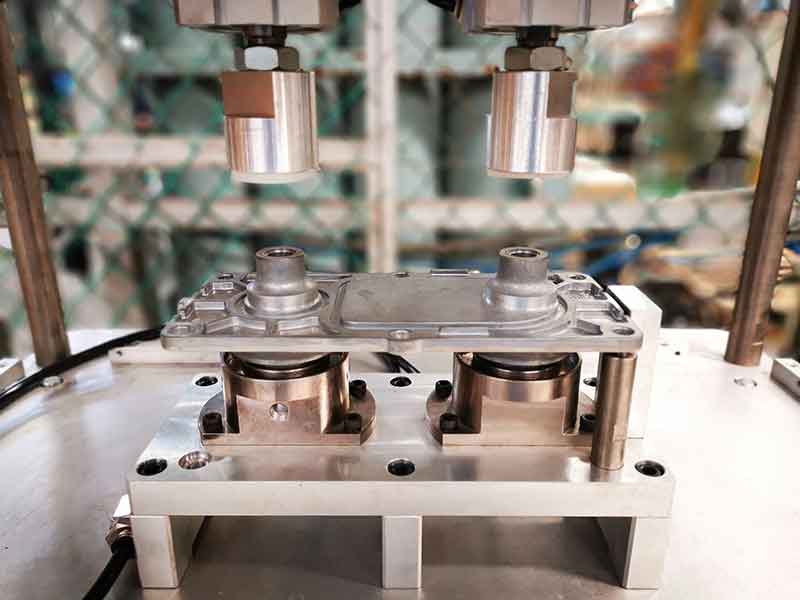

The process of diecasting starts with the preparation of high-quality steel molds, known as dies. Dies are constructed to withstand the intense pressures and high temperatures that molten metal experiences. Dies are carefully designed to preserve intricate detail and keep tight tolerances making sure that every part cast has the right specifications. When casting is performed, metals such as aluminum, magnesium, zinc, and copper are melted and then in the cavity of the die in high-pressure. This quick injection, and its subsequent cooling results in components that exhibit excellent quality and stability in dimensionality as well as a flawless appearance. The precision of the dies allow for the development of components with complex geometries that are usually impossible with other methods of production.

One of the major advantages of diecasting is its ability to create parts that have high quality and precision and smooth surface finishing. Diecasting with high pressure ensures the molten metal is precisely molded in the mold which results in parts that require minimal in terms of machining or finish. This kind of precision is ideal in the production of complex geometries as well as thin-walled pieces that would be difficult to create or not possible with other manufacturing methods. Furthermore, the process can create pieces with tight tolerances as well as exceptional repeatability. This makes it perfect for large-scale production. Diecasting's efficiency will also lead to savings in costs because the higher productivity rates cut down on labor and waste material.

Diecasting is also a great option with regard to mechanical properties as well as performance. Parts produced through diecasting are recognized as durable and strong as they are the most important qualities for parts that are used in harsh environments. The fine-grain structure that forms as a result of the fast cooling process the metal helps to create these excellent properties, which make diecast pieces suitable for use in highly stressed environments. Additionally, diecasting permits the inclusion of thin walls and complicated characteristics without jeopardizing the integrity of the finished product. This can be particularly useful when it comes to aerospace and automotive industries where the ability to reduce weight while maintaining structural strength can be crucial to boost fuel efficiency and overall performance. To obtain supplementary information please go to www.senadiecasting.com.my/

Diecasting's materials play a crucial role in determining the characteristics and efficiency of the final product. Aluminum is one of the most widely used components because of its superior strength-to-weight ratio, resistance to corrosion, and excellent thermal and electrical conductivity. Zinc alloys also have a cult following providing high durability, strength, and the capability of creating components with fine specifics. Magnesium alloys benefit from the advantages that they are the tiniest structural metal, making them ideal for applications where weight reduction is crucial. Copper alloys, although less common, are used because of their outstanding electro-conductive properties and corrosion resistance. The material selection depends on the particular requirements of the job, such as mechanical properties, physical conditions in the environment, and also cost aspects.

Diecasting is a very efficacious and versatile manufacturing process which is essential to the production of complicated metal parts that have high precision and consistency. Its capability to make components with fine details as well as tight tolerances and flawless surface finish makes it indispensable across a range of fields, from automotive to aerospace to consumer electronics and beyond. The use of different materials further enhances the versatility of diecasting. It allows companies to select the ideal alloy that meets their particular needs. With the advancement of technology and as the demand for premium, economical components is growing and increase, diecasting will continue to be crucial for manufacturing, driving innovation and excellence within the production.